At Rethink Plastic, we have carried out our own evaluation of the SUP Directive with the contribution of the Break Free From Plastic Network, building on the previous transposition and implementation assessments published by the Rethink Plastic alliance to monitor developments since 2019, as well as recent assessments from our members on the state of play in their respective countries. We will also take this opportunity to highlight the positive impact that the SUP Directive has had, both in raising general awareness about single-use plastic pollution and promoting a preventative approach to the global plastic pollution crisis, as opposed to relying on a clean-up and recycling-focused mitigation approach.

Why plastic pellets must be addressed in the treaty

To prevent pellet loss the treaty text must include:

- All plastic feedstocks (including primary, recycled, fossil fuel and biomass derived plastic in flakes, powder or pellet forms

- All sectors & companies (including producers, converters, waste handlers, transporters and actors who handle pellets)

- Mandatory loss prevention measures with specific minimum requirements

- Requirements for independent standards and certification schemes to

demonstrate compliance.

Risks of Plastic Pellet Losses along the value chain

Plastic pellets are lost at all stages of the plastics value chain. The EU needs to address this issue with an ambitious Plastic Pellets regulation.

Prioritising plastics and polymers in the ESPR – Briefing

Plastics and polymers need to be included as an intermediate product in the first working plan under the EU Ecodesign for Sustainable Products Regulation (ESPR) – foreseen for early 2025. By prioritising plastics and polymers in the first ESPR working plan, the EU will take a major step in addressing the plastic pollution crisis, and work towards minimising the environmental footprint of plastic and polymer production.

Strengthening EU Rules on Pellet Loss: A necessary move to prevent the damage and reduce the cost of microplastic pollution

Rethink Plastic’s position on the EU’s regulation to prevent pellet loss: To effectively reduce the environmental and economic burden of pellet loss, a comprehensive supply chain approach is essential to implement, with robust and binding measures for all operators at every stage of the supply chain, ensuring that those responsible for pollution are held accountable rather than leaving EU public authorities and citizens to pay. Such binding prevention steps will protect public health and ecosystems while cutting long-term costs for European communities by curbing the ongoing effects of microplastic pollution.

PVC – Frequently Asked Questions

What is PVC and what is it used for? Why is PVC dangerous? If PVC has alternatives, why is it not already being replaced? What regulatory measures do NGOs ask for? Answers to frequently asked questions about PVC (polyvinyl chloride).

A holistic plastic strategy: Addressing polymers and plastics under the ESPR

Plastics and polymers should be included as an intermediate product in the first working plan

under the Ecodesign for Sustainable Products Regulation (foreseen for early 2025). By prioritising

plastics and polymers in the first ESPR working plan, the EU will take a major step in addressing

the plastic pollution crisis, working to minimise the environmental footprint of plastic and polymer

production. This paper showcases the need to do that and shed lights on the missing pieces of the

puzzle and limitation of current methodology that look into polymer production.

PVC Problem Very Clear.

Commonly used plastics pose many threats to human health and the environment, making them one of the most pressing environmental issues of our time. But in the landscape of the various plastics that surround us, polyvinyl chloride (PVC) stands out. Not only is it found everywhere, from home furnishings to children’s toys and medical supplies, contributing to widespread, irreversible plastic pollution, but it is also associated with grave toxic effects along its whole life cycle – from production to disposal.

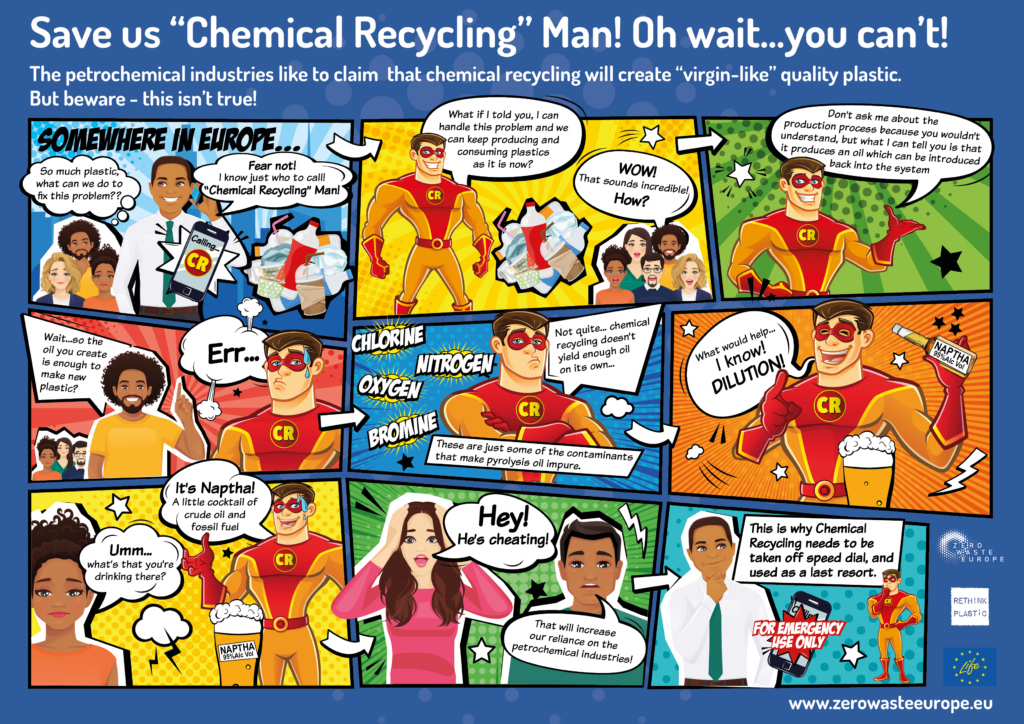

Save us “Chemical Recycling” Man! Oh wait…you can’t!

Meet “Chemical Recycling” Man. Not your run-of-the-mill comic book superhero. This one is propped up by the petrochemical industries.

These industries like to claim that chemical recycling will create “virgin-like” quality plastic. But beware – this isn’t true! Because of low oil yields and contamination, pyrolysis oil must be diluted by a mixture made up of crude oil, derived from fossil fuel (in some cases by a ratio of over 40:1!). Chemical recycling treatment cannot process the diversity of post-consumer plastic waste.

In this handy infographic, developed from Zero Waste Europe’s Leaky Loop ‘Recycling’ report, we visualise the weakness of “chemical recycling” as a method of recycling by personifying “Chemical Recycling” as an arrogant superhero who thinks they can save us all, only to meet their ‘kryptonite’ through the demands of the public for virgin-like quality.